Torque Wrenches

-

kbrothers

- Posts: 258

- Joined: Mon Sep 06, 2010 6:38 am

- First and Last Name: Ken Brothers

- Location: Ebensburg, PA

Torque Wrenches

Is there any way to use a foot pound torque wrench for inch pounds? Is there a formula to change one to the other? Need to get my 20 mag back together Thanks Ken in Pa

-

Ben Morong

- Posts: 139

- Joined: Thu Sep 09, 2010 7:04 am

- First and Last Name: Ben Morong

- Location: Southern ME

Re: Torque Wrenches

Someone correct me if I'm wrong, but I think 12 inch-pounds equals 1 foot-pound. You may want to use an inch-pound wrench though, just as it would provide a finer adjustment.

Cub Cadet Originals -- Ayuh! (and a couple of 124's, 125's, and a 1650 -- Yep!)

- Jeff in Pa

- Posts: 665

- Joined: Sun Sep 12, 2010 8:06 am

- First and Last Name: Jeff Derstine

- Location: Zionsville,PA

Re: Torque Wrenches

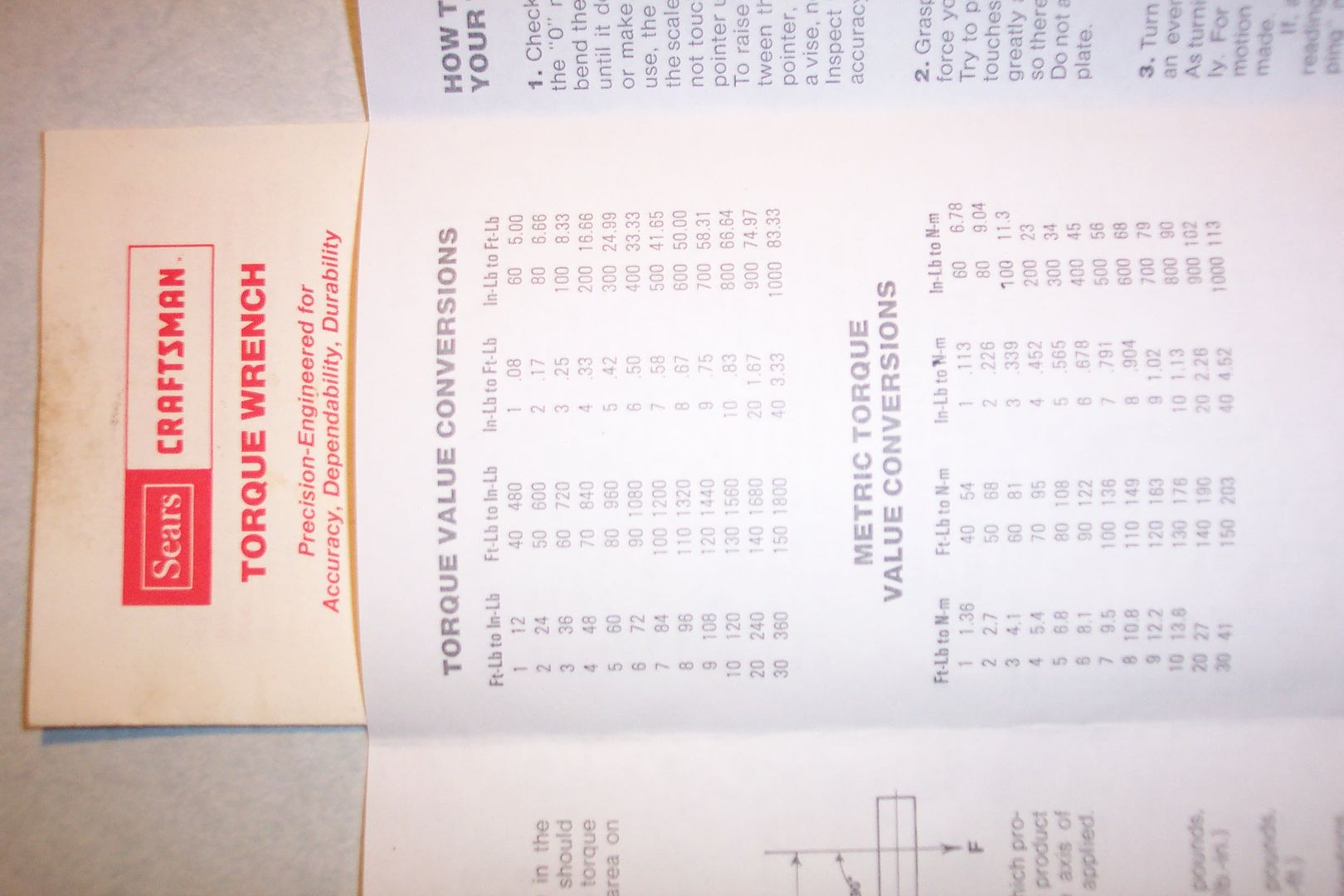

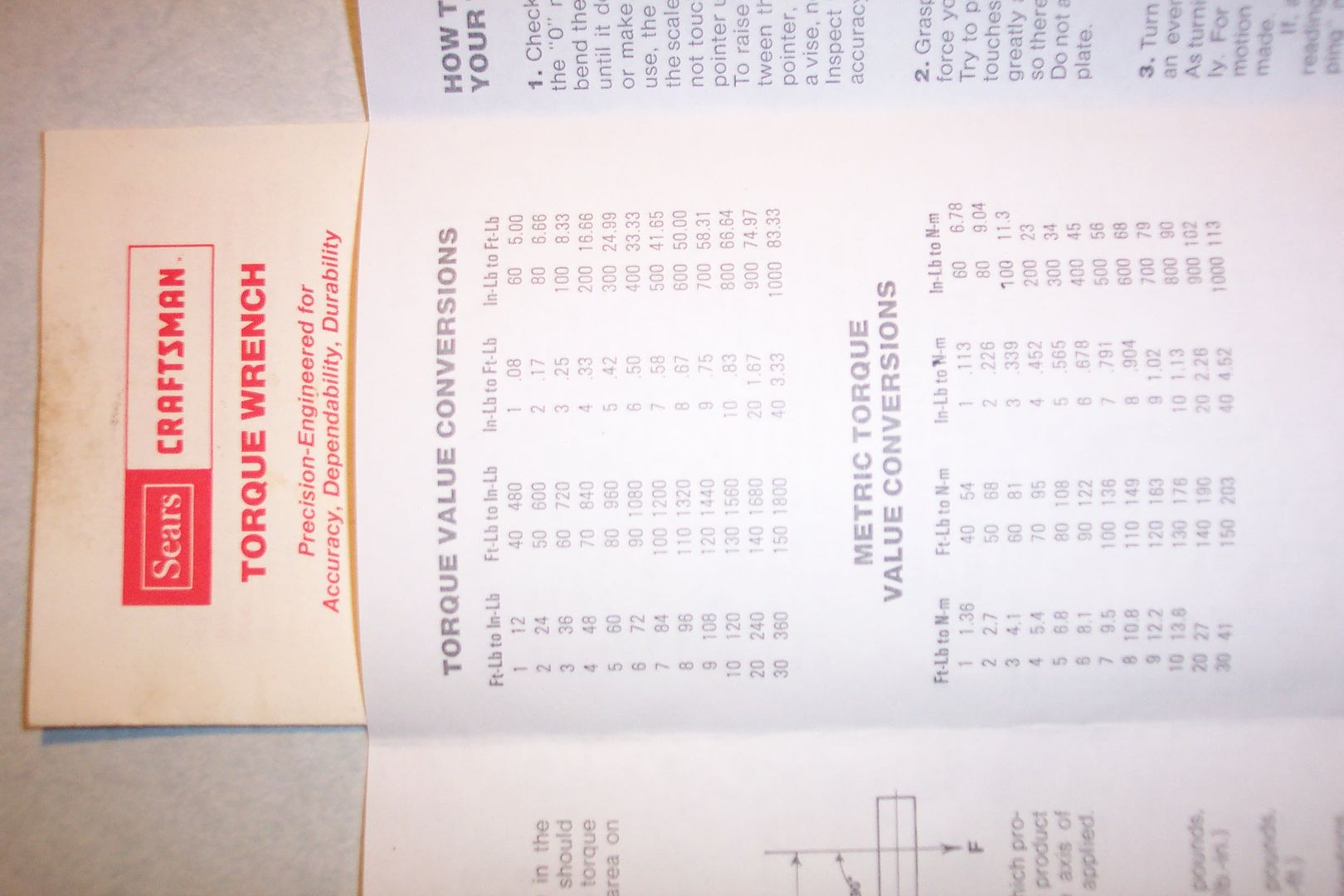

I have a Craftsman Inch Pound torque wrench, here's a copy of the conversion chart in it.

Jeff

Jeff

125 & 125 with hydraulic lift

- BigMike

- Posts: 1359

- Joined: Mon Sep 06, 2010 8:45 pm

- First and Last Name: Mike Andrews

- Location: Niles,Michigan

Re: Torque Wrenches

Ken,dividing by 12 does work but you also loose some accuracy.I have used that method on many motors without a failure yet.

I have tried to find a torque wrench that would cover the range we use on our Kohlers but have not found anything as of yet.

I have tried to find a torque wrench that would cover the range we use on our Kohlers but have not found anything as of yet.

- mgonitzke

- Posts: 392

- Joined: Mon Sep 06, 2010 5:43 pm

- First and Last Name: Matt Gonitzke

- Location: Wichita, KS

Re: Torque Wrenches

This is why I have two torque wrenches to use: one in in-lbs, one in ft-lbs. Divide in-lbs. by 12 to get foot pounds (there's 12 inches in a foot) but as Mike says, you'll lose accuracy going from in-lbs to ft-lbs.

Original, 582 w/ 18 hp Kohler Command, 682 w/ Kwik-Way loader, 782, 782D, 1872 My Cub Site

- Tom Scott

- Chief Moderator

- Posts: 1776

- Joined: Mon Sep 06, 2010 9:11 pm

- First and Last Name: Tom Scott

- Location: Bentley Springs, Maryland

Re: Torque Wrenches

To be more specific, it is not the conversion from inch-lb to foot-lb that affects the accuracy, but the fact that you are probably not using a wrench that is at it's best accuracy window. You don't want to be down at the extreme low end or up at the extreme high end of the torque wrench's range. This is why torque wrench's ranges overlap a good bit, to keep you away from the extremes. If you convert from one unit to the other, just make sure you are at least somewhere in the middle 80% of the range of the wrench you are going to use. Generally, but not always, if the spec is given in inch-lb and you have a wrench marked in ft-lb, you may be operating too low in the range of the wrench for good accuracy.

Best to use a "clicker" type wrench as opposed to a beam type in most applications as well.

Best to use a "clicker" type wrench as opposed to a beam type in most applications as well.

1872, 46", 50C decks, Haban dozer blade, 450 snow blower

2182-1, Kwik-Way Loader, 3-pt & rear pto, 442 tiller

2182-2, 54" deck, 551 snow blower

Past tractors: 1541, 2135

<><

2182-1, Kwik-Way Loader, 3-pt & rear pto, 442 tiller

2182-2, 54" deck, 551 snow blower

Past tractors: 1541, 2135

<><

- l palma

- Posts: 738

- Joined: Mon Sep 06, 2010 9:46 am

- First and Last Name: Lew Palma

- Location: Montague, N.J.

Re: Torque Wrenches

What about the Dial type?

How are they for Accuracy????

Mine is a Snap On

How are they for Accuracy????

Mine is a Snap On

- Tom Scott

- Chief Moderator

- Posts: 1776

- Joined: Mon Sep 06, 2010 9:11 pm

- First and Last Name: Tom Scott

- Location: Bentley Springs, Maryland

Re: Torque Wrenches

I haven't researched them specifically, but I have not heard of any reason that the dial types are a problem. The advantage of the clicker type is that you don't have to be watching a guage or dial as you approach the correct torque, and they let go momentarily and produce an audible click when you have reached the preset torque. If you can be in a position to read the gauge or dial as you approach the correct torque then you should be able to torque accurately.

This of course assumes that the torque wrench was of quality manufacture, has not been dropped, pulled at an odd angle, abused in some other fashion, or even looked at sideways. Torque wrenches are fragile items that I just won't loan out for that reason. I had one that was never dropped or abused that had the main calibaration nut loosen up inside, so it is ruined until I can build a rig to recalibrate it. I bought a replacement, because I couldn't wait.

Remember that torque is an indirect reading of what you really want: bolt tension. Much of the torque required to turn the bolt is used against friction of the threads and head against the thrust surface. As bolt tension is very hard to measure, the torque reading is usually the best that can be done outside of laboratory conditions.

To ensure that friction doesn't unduly provide a false torque reading, make sure you run a tap through the block holes and clean them real good. Use the recommended hardware, and install clean and dry, or oiled, depending upon the torque specification. (Good general charts will provide a clean torque spec versus an oiled spec; due to the friction component the oiled spec will always be lower to provide the same tension.) For an engine, follow the manual. They should tell you how to prepare the bolts. Also, don't stop turning as you approach the correct torque; due to the increased friction from rest (static friction). The most accurate reading is obtained while the wrench is still turning; this is another advantage of the clicker type as it is hard to read a dial while it is moving.

You should be able to Google for the manufacturer of the torque wrench for the accuracy scale. Usually they are given as at least two ranges; one accuracy for the extreme limits of the wrench, and a slightly more accurate percentage for the middle of the range. I would not use a torque wrench that I did not know the history of without calibrating it.

This of course assumes that the torque wrench was of quality manufacture, has not been dropped, pulled at an odd angle, abused in some other fashion, or even looked at sideways. Torque wrenches are fragile items that I just won't loan out for that reason. I had one that was never dropped or abused that had the main calibaration nut loosen up inside, so it is ruined until I can build a rig to recalibrate it. I bought a replacement, because I couldn't wait.

Remember that torque is an indirect reading of what you really want: bolt tension. Much of the torque required to turn the bolt is used against friction of the threads and head against the thrust surface. As bolt tension is very hard to measure, the torque reading is usually the best that can be done outside of laboratory conditions.

To ensure that friction doesn't unduly provide a false torque reading, make sure you run a tap through the block holes and clean them real good. Use the recommended hardware, and install clean and dry, or oiled, depending upon the torque specification. (Good general charts will provide a clean torque spec versus an oiled spec; due to the friction component the oiled spec will always be lower to provide the same tension.) For an engine, follow the manual. They should tell you how to prepare the bolts. Also, don't stop turning as you approach the correct torque; due to the increased friction from rest (static friction). The most accurate reading is obtained while the wrench is still turning; this is another advantage of the clicker type as it is hard to read a dial while it is moving.

You should be able to Google for the manufacturer of the torque wrench for the accuracy scale. Usually they are given as at least two ranges; one accuracy for the extreme limits of the wrench, and a slightly more accurate percentage for the middle of the range. I would not use a torque wrench that I did not know the history of without calibrating it.

1872, 46", 50C decks, Haban dozer blade, 450 snow blower

2182-1, Kwik-Way Loader, 3-pt & rear pto, 442 tiller

2182-2, 54" deck, 551 snow blower

Past tractors: 1541, 2135

<><

2182-1, Kwik-Way Loader, 3-pt & rear pto, 442 tiller

2182-2, 54" deck, 551 snow blower

Past tractors: 1541, 2135

<><

-

kbrothers

- Posts: 258

- Joined: Mon Sep 06, 2010 6:38 am

- First and Last Name: Ken Brothers

- Location: Ebensburg, PA

Re: Torque Wrenches

Thanks a lot guys What a group! Going out after work today and buy an inch pound wrench What a wealth of Know How and Can Do on this site Ken(feeling a little more confident) in Pa

- Racenitro

- Posts: 354

- Joined: Tue Sep 07, 2010 10:31 pm

- First and Last Name: Frank S. Morski

- Location: O'Fallon, Il

Re: Torque Wrenches

Torque wrenches work on the Moment Arm principle. Force applied at a distance from pivot point.

So 1# applied at 12"(1ft) from the pivot point equals 1FT-LB. (Force must be applied at a perpendicular to the line from the point of application tot he pivot point.)

1# at 18" equals 1 1/2 FT-LB.

All of this is compensated for by the design of the various torque wrenches.

Mechanics for Engineers (Statics)

Matt...You have definitely been through this course...LOL

I last took mine 35 years ago...but nothing should have changed.

So 1# applied at 12"(1ft) from the pivot point equals 1FT-LB. (Force must be applied at a perpendicular to the line from the point of application tot he pivot point.)

1# at 18" equals 1 1/2 FT-LB.

All of this is compensated for by the design of the various torque wrenches.

Mechanics for Engineers (Statics)

Matt...You have definitely been through this course...LOL

I last took mine 35 years ago...but nothing should have changed.

-

wdeturck

Re: Torque Wrenches

I worked in a small engine shop and the boss never used a torque wrench(mostly B&S engines) and he would actually over tighten them. I asked him one day and he said he has never had an engine come back with a blown head gasket? He said he followed B&S method and had trouble with head gaskets and just changed to that method and worked for him.

- J Hayes

- Posts: 919

- Joined: Mon Sep 06, 2010 6:20 pm

- First and Last Name: Jim Hayes

- Location: Apollo Pa

Re: Torque Wrenches

I had this calculator on the old forum, can it be placed on tools, or faq's ?

http://www.unitconversion.org/energy/in ... rsion.html

http://www.unitconversion.org/energy/in ... rsion.html

My mind wants a Divorce ?? .

-

MattS

- Posts: 74

- Joined: Sat Sep 11, 2010 6:32 am

- First and Last Name: Matthew Spinazzola

- Location: Wilmingon, DE 19808

Re: Torque Wrenches

The dial or beam type torque wrenches are needed for measuring rotational torque, such as bearing pre-load.

- VScott

- Posts: 362

- Joined: Wed Sep 15, 2010 8:47 pm

- First and Last Name: V Scott

- Location: St.Louis, Mo

Re: Torque Wrenches

I have been in this argument 100 times, and I will always think that I'm right so here is my two cent's worth.

Whatever you do,

Zero the tool when not in use

Keep it clean, and in a good fitting case

Don't use it for a breaker bar

Don't loan them out because the above items usually are not a priority for someone who borrows yours. They can be a major investment, and you want it to work when YOU need it.

Most Snap-on Mac,etc tool van operators will check the calibration for you for free. I had a 1/2" drive 30 to 150 ft lbs clicker that I lent out to a friend. It came back in the case the wrong way with one latch on the case broken, and looking like he used it to overhaul a locomotive. Was set on 150 ft lbs. It no longer works. I found this out torquing a valve body in a th350 transmission. I was not amused.

Whatever you do,

Zero the tool when not in use

Keep it clean, and in a good fitting case

Don't use it for a breaker bar

Don't loan them out because the above items usually are not a priority for someone who borrows yours. They can be a major investment, and you want it to work when YOU need it.

Most Snap-on Mac,etc tool van operators will check the calibration for you for free. I had a 1/2" drive 30 to 150 ft lbs clicker that I lent out to a friend. It came back in the case the wrong way with one latch on the case broken, and looking like he used it to overhaul a locomotive. Was set on 150 ft lbs. It no longer works. I found this out torquing a valve body in a th350 transmission. I was not amused.

-

Klapatta

- Posts: 1364

- Joined: Mon Sep 06, 2010 2:25 pm

- First and Last Name: Kenneth LaPatta

- Location: Rockingham VT.

Re: Torque Wrenches

We have dozens of torque wrenches out on the production floor at any given time ranging from 30 inch pound dial types to the 150 foot pound clicker types- all are required to pass regular calibration tests. By far the ones that require the most attention are the clicker types in the 50 to 150 foot pound ranges. These seem to have the need to be rebuilt or replaced on a regular basis. While some operators are more abusive than others it would seem that it does not take much to knock them out of whack- even a rather small rap will throw them way out. The rebuild cost for this is nearly the amount of replacement and unless it's a special application tool it usually gets shelved.

One other bad thing about the clicker types is that there is no type of visual inspection that can help to indicate a failure such as a cracked bezel or misaligned pointer and it can pass through hundreds of cycles before being detected. Not acceptable. I am not a big fan of them for those reasons and prefer the old fashion beam and pointer type for my own work.

One other bad thing about the clicker types is that there is no type of visual inspection that can help to indicate a failure such as a cracked bezel or misaligned pointer and it can pass through hundreds of cycles before being detected. Not acceptable. I am not a big fan of them for those reasons and prefer the old fashion beam and pointer type for my own work.

- Tim DeLooza

- Posts: 148

- Joined: Mon Sep 06, 2010 6:57 am

- First and Last Name: Tim DeLooza

- Location: Penn Yan, NY

Re: Torque Wrenches

This may be a little to “new” for some, but I have a Snap-On TechWrench. What sold me on it is that it covers all the ranges that we deal with for the Kohler engines. For ease of use, a clicker is the way to go, but like others have said you would need two to cover the inch pound range and foot pound rage. This wrench isn’t really for everyone though as it can be temperamental at times. It’s best to be able to see the numbers as your torqueing so you can be ready for the “beep”. It does also eat batteries like crazy.

-

Josh O

- Posts: 22

- Joined: Mon Oct 04, 2010 9:09 am

- First and Last Name: Josh Ott

- Location: Oakfield, Wi

Re: Torque Wrenches

To convert foot pounds to inch pounds, multiply by 12.

To convert inch pounds to foot pounds, divide by 12

To convert inch pounds to foot pounds, divide by 12

Cub Cadets are like potato chips...you cant just have one.

- Racenitro

- Posts: 354

- Joined: Tue Sep 07, 2010 10:31 pm

- First and Last Name: Frank S. Morski

- Location: O'Fallon, Il

Re: Torque Wrenches

I use my beam torque wrench to check my clickers.....

Vinnie. I NEVER will loan out any of my torque wrenches.

Have to tell a funny torquing story from years ago..

Had a friend everybody called Gomer...he was a junk yard character and the his junk was many layers deep but he knew where everyting was. A guy called him about the torque on the heads of a 50's mercury. Gomer told him to tighten them down till you could not turn them any more and then back them off two turns. Well the idiot did this and it leaked like a seive. The idiot called gomer an was complaining about gomer not knowing what he was talking about...gomer stopped him and said...if you wanted it torqued right, bring it to me and pay my rate...otherwise, I will tell you anyting on the phone just to get you off.

Vinnie. I NEVER will loan out any of my torque wrenches.

Have to tell a funny torquing story from years ago..

Had a friend everybody called Gomer...he was a junk yard character and the his junk was many layers deep but he knew where everyting was. A guy called him about the torque on the heads of a 50's mercury. Gomer told him to tighten them down till you could not turn them any more and then back them off two turns. Well the idiot did this and it leaked like a seive. The idiot called gomer an was complaining about gomer not knowing what he was talking about...gomer stopped him and said...if you wanted it torqued right, bring it to me and pay my rate...otherwise, I will tell you anyting on the phone just to get you off.

- J Hayes

- Posts: 919

- Joined: Mon Sep 06, 2010 6:20 pm

- First and Last Name: Jim Hayes

- Location: Apollo Pa

Re: Torque Wrenches

Or use this .Josh O wrote:To convert foot pounds to inch pounds, multiply by 12.

To convert inch pounds to foot pounds, divide by 12

http://www.unitconversion.org/energy/in ... rsion.html

My mind wants a Divorce ?? .

-

Josh O

- Posts: 22

- Joined: Mon Oct 04, 2010 9:09 am

- First and Last Name: Josh Ott

- Location: Oakfield, Wi

Re: Torque Wrenches

Or yes thats works too. lol. pretty neat.

Cub Cadets are like potato chips...you cant just have one.